- Home

- COSTA™ Technology

- Products

- HANU™ Flow Reactors

- Laboratory R&D

- HANU™ 2X 5

- Accessories

- Inlays

- HANU™ 2X 5 Inlay, cubic 2x2, stainless steel

- HANU™ 2X 5 Inlay, cubic 2x2, Hastelloy

- HANU™ 2X 5 Inlay, cubic 2x2, copper

- HANU™ 2X 5 Inlay, cubic 2x2, PTFE

- HANU™ 2X 5 Inlay, cubic 2x2, silicon carbide

- HANU™ 2X 5 Inlay, cubic 2x2, PEEK

- HANU™ 2X 5 Inlay, cubic 2x2, titanium

- HANU™ 2X 5 Inlay, cubic 1x1, Hastelloy

- HANU™ 2X 5 Inlay, cubic 1x1, Stainless steel

- In/outlet Ports

- Consumables

- Miscellaneous

- Inlays

- Accessories

- HANU™ 2X 5

- Process Development

- Pilot/Production

- Laboratory R&D

- MPDS® for Photochemistry

- Electrochemistry

- Previous Models

- HANU™ Flow Reactors

- Applications

- Application Notes

- Application Note 5: Electrochemical Oxidation of Diphenyl Sulfide enabled by the FAVO™ 5 Flow Reactor

- Application Note 4: Temperature Control in the HANU™ PX 9 Parallel Photoreactor

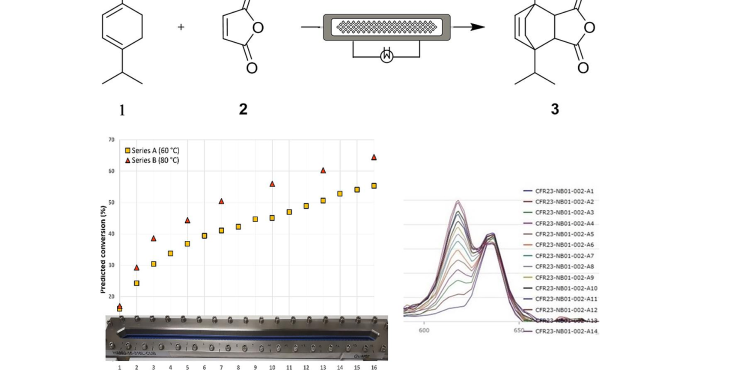

- Application Note 3: The use of the HANU™ reactor in combination with non-invasive inline Raman spectroscopy as a tool for a real

- Application Note 2: Photoinitiated thiol-ene coupling in flow

- Application Note 1: Synthesis of Cookson’s diketone via intramolecular [2+2] photocycloaddition

- Publications

- Scientific Publications

- 2022 | Chem. Eur. J. | Photochemical Deracemization of a Medicinally-Relevant Benzopyran using an Oscillatory Flow Reactor

- 2021 | Green Chem. | Continuous flow heterogeneous catalytic reductive aminations under aqueous micellar conditions

- 2021 | Green Chem. | Continuous Flow Processing of Bismuth-Photocatalyzed Atom Transfer Radical Addition Reactions Using an

- 2020 | Org. Process Res. Dev. | Optimization of a Decatungstate-Catalyzed C(Sp 3 )–H Alkylation Using a Continuous Oscillatory

- 2020 | Org. Process Res. Dev. | Ir/Ni Photoredox Dual Catalysis with Heterogeneous Base Enabled by an Oscillatory Plug Flow

- 2020 | React. Chem. Eng. | An Oscillatory Plug Flow Photoreactor Facilitates Semi-Heterogeneous Dual Nickel/Carbon Nitride

- Magazine Articles

- Scientific Publications

- Areas of Interest

- Application Notes

- Events

- Jobs

- About us

- Contact

- Application Notes

- Application Note 5: Electrochemical Oxidation of Diphenyl Sulfide enabled by the FAVO™ 5 Flow Reactor

- Application Note 4: Temperature Control in the HANU™ PX 9 Parallel Photoreactor

- Application Note 3: The use of the HANU™ reactor in combination with non-invasive inline Raman spectroscopy as a tool for a real

- Application Note 2: Photoinitiated thiol-ene coupling in flow

- Application Note 1: Synthesis of Cookson’s diketone via intramolecular [2+2] photocycloaddition

- Publications

- Scientific Publications

- 2022 | Chem. Eur. J. | Photochemical Deracemization of a Medicinally-Relevant Benzopyran using an Oscillatory Flow Reactor

- 2021 | Green Chem. | Continuous flow heterogeneous catalytic reductive aminations under aqueous micellar conditions

- 2021 | Green Chem. | Continuous Flow Processing of Bismuth-Photocatalyzed Atom Transfer Radical Addition Reactions Using an

- 2020 | Org. Process Res. Dev. | Optimization of a Decatungstate-Catalyzed C(Sp 3 )–H Alkylation Using a Continuous Oscillatory

- 2020 | Org. Process Res. Dev. | Ir/Ni Photoredox Dual Catalysis with Heterogeneous Base Enabled by an Oscillatory Plug Flow

- 2020 | React. Chem. Eng. | An Oscillatory Plug Flow Photoreactor Facilitates Semi-Heterogeneous Dual Nickel/Carbon Nitride

- Magazine Articles

- Scientific Publications

- Areas of Interest