- Home

- COSTA™ Technology

- Products

- HANU™ Flow Reactors

- Laboratory R&D

- HANU™ 2X 5

- Accessories

- Inlays

- HANU™ 2X 5 Inlay, cubic 2x2, stainless steel

- HANU™ 2X 5 Inlay, cubic 2x2, Hastelloy

- HANU™ 2X 5 Inlay, cubic 2x2, copper

- HANU™ 2X 5 Inlay, cubic 2x2, PTFE

- HANU™ 2X 5 Inlay, cubic 2x2, silicon carbide

- HANU™ 2X 5 Inlay, cubic 2x2, PEEK

- HANU™ 2X 5 Inlay, cubic 2x2, titanium

- HANU™ 2X 5 Inlay, cubic 1x1, Hastelloy

- HANU™ 2X 5 Inlay, cubic 1x1, Stainless steel

- In/outlet Ports

- Consumables

- Miscellaneous

- Inlays

- Accessories

- HANU™ 2X 5

- Process Development

- Pilot/Production

- Laboratory R&D

- FAVO™ for Electrochemistry

- Previous Models

- HANU™ Flow Reactors

- Applications

- Application Notes

- Application Note 5: Electrochemical Oxidation of Diphenyl Sulfide enabled by the FAVO™ 5 Flow Reactor

- Application Note 4: Temperature Control in the HANU™ PX 9 Parallel Photoreactor

- Application Note 3: The use of the HANU™ reactor in combination with non-invasive inline Raman spectroscopy as a tool for a real

- Application Note 2: Photoinitiated thiol-ene coupling in flow

- Application Note 1: Synthesis of Cookson’s diketone via intramolecular [2+2] photocycloaddition

- Publications

- Scientific Publications

- 2022 | Chem. Eur. J. | Photochemical Deracemization of a Medicinally-Relevant Benzopyran using an Oscillatory Flow Reactor

- 2021 | Green Chem. | Continuous flow heterogeneous catalytic reductive aminations under aqueous micellar conditions

- 2021 | Green Chem. | Continuous Flow Processing of Bismuth-Photocatalyzed Atom Transfer Radical Addition Reactions Using an

- 2020 | Org. Process Res. Dev. | Optimization of a Decatungstate-Catalyzed C(Sp 3 )–H Alkylation Using a Continuous Oscillatory

- 2020 | Org. Process Res. Dev. | Ir/Ni Photoredox Dual Catalysis with Heterogeneous Base Enabled by an Oscillatory Plug Flow

- 2020 | React. Chem. Eng. | An Oscillatory Plug Flow Photoreactor Facilitates Semi-Heterogeneous Dual Nickel/Carbon Nitride

- Magazine Articles

- Scientific Publications

- Areas of Interest

- Application Notes

- Events

- Jobs

- About us

- Contact

- HANU™ Flow Reactors

- Laboratory R&D

- HANU™ 2X 5

- Accessories

- Inlays

- HANU™ 2X 5 Inlay, cubic 2x2, stainless steel

- HANU™ 2X 5 Inlay, cubic 2x2, Hastelloy

- HANU™ 2X 5 Inlay, cubic 2x2, copper

- HANU™ 2X 5 Inlay, cubic 2x2, PTFE

- HANU™ 2X 5 Inlay, cubic 2x2, silicon carbide

- HANU™ 2X 5 Inlay, cubic 2x2, PEEK

- HANU™ 2X 5 Inlay, cubic 2x2, titanium

- HANU™ 2X 5 Inlay, cubic 1x1, Hastelloy

- HANU™ 2X 5 Inlay, cubic 1x1, Stainless steel

- In/outlet Ports

- Consumables

- Miscellaneous

- Inlays

- Accessories

- HANU™ 2X 5

- Process Development

- Pilot/Production

- Laboratory R&D

- FAVO™ for Electrochemistry

- Previous Models

- Home

- Products

- HANU™ Flow Reactors

- Pilot/Production

- HANU™ HX 150

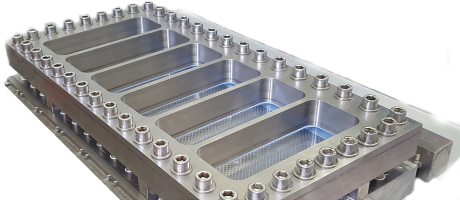

HANU™ HX 150 Flow Reactor

To further scale up your (photo)chemical process, the HANU™ HX 150 Flow Reactor was developed. By simply widening the process channel, the internal volume of the reactor is increased by ten-fold (150 ml), and thanks to the innovative COSTA™ technology, all the crucial process characteristics - process path length, irradiation properties, mass and heat transfer, residence time distribution and so on – remain unaffected.

Ajinomoto Bio-Pharma Services will soon have a scaled-up HANU™ HX 150 Flow Reactor in operation at its cGMP pilot plant in Wetteren, Belgium.

User Applications:

Pilot & production phase

Pilot & production phase

UV & VIS photochemistry

UV & VIS photochemistry

Hard-to-flow multi-phase processes (e.g. slurry-based)

Hard-to-flow multi-phase processes (e.g. slurry-based)

Continuous processes requiring longer residence times (type B & C reactions, up to hour range!)

Continuous processes requiring longer residence times (type B & C reactions, up to hour range!)

Compatible with highly corrosive media

Compatible with highly corrosive media

cGMP compliant

cGMP compliant

Specifications:

| Internal volume | 150 mL |

| Transparent window | Borosilicate or quartz |

| Temp. Range | -20 to 80 °C |

| Max. operational press. |

10 bar |

| Material of construction | Stainless steel 316L |

| Wetted parts | Stainless steel 316L or Hastelloy C276, PTFE, FFKM, FEP |

| Inlay material options | Stainless steel 316L or Hastelloy C276 customized upon request |

| Mixing elements pattern | 2x2 mm cuboids customized upon request |

| Process ports | 1/4” NPT Female |

| Heat exchanger | Heat transfer fluid system |

| Recommended Throughput | 0.15 - 60 L/h (kg/h to MT/y) |

| Outer dimensions | 58 x 46 x 12 cm (L x W x H) |

| Gaskets | ABS Certified, FDA Compliant, REACH Compliant, RoHS Compliant, USP VI 87 Compliant, USP VI 88 Compliant, USP VI 661 Compliant, ADI/TSE Free |