- Home

- COSTA™ Technology

- Products

- HANU™ Flow Reactors

- Laboratory R&D

- HANU™ 2X 5

- Accessories

- Inlays

- HANU™ 2X 5 Inlay, cubic 2x2, stainless steel

- HANU™ 2X 5 Inlay, cubic 2x2, Hastelloy

- HANU™ 2X 5 Inlay, cubic 2x2, copper

- HANU™ 2X 5 Inlay, cubic 2x2, PTFE

- HANU™ 2X 5 Inlay, cubic 2x2, silicon carbide

- HANU™ 2X 5 Inlay, cubic 2x2, PEEK

- HANU™ 2X 5 Inlay, cubic 2x2, titanium

- HANU™ 2X 5 Inlay, cubic 1x1, Hastelloy

- HANU™ 2X 5 Inlay, cubic 1x1, Stainless steel

- In/outlet Ports

- Consumables

- Miscellaneous

- Inlays

- Accessories

- HANU™ 2X 5

- Process Development

- Pilot/Production

- Laboratory R&D

- MPDS® for Photochemistry

- Electrochemistry

- Previous Models

- HANU™ Flow Reactors

- Applications

- Application Notes

- Application Note 5: Electrochemical Oxidation of Diphenyl Sulfide enabled by the FAVO™ 5 Flow Reactor

- Application Note 4: Temperature Control in the HANU™ PX 9 Parallel Photoreactor

- Application Note 3: The use of the HANU™ reactor in combination with non-invasive inline Raman spectroscopy as a tool for a real

- Application Note 2: Photoinitiated thiol-ene coupling in flow

- Application Note 1: Synthesis of Cookson’s diketone via intramolecular [2+2] photocycloaddition

- Publications

- Scientific Publications

- 2022 | Chem. Eur. J. | Photochemical Deracemization of a Medicinally-Relevant Benzopyran using an Oscillatory Flow Reactor

- 2021 | Green Chem. | Continuous flow heterogeneous catalytic reductive aminations under aqueous micellar conditions

- 2021 | Green Chem. | Continuous Flow Processing of Bismuth-Photocatalyzed Atom Transfer Radical Addition Reactions Using an

- 2020 | Org. Process Res. Dev. | Optimization of a Decatungstate-Catalyzed C(Sp 3 )–H Alkylation Using a Continuous Oscillatory

- 2020 | Org. Process Res. Dev. | Ir/Ni Photoredox Dual Catalysis with Heterogeneous Base Enabled by an Oscillatory Plug Flow

- 2020 | React. Chem. Eng. | An Oscillatory Plug Flow Photoreactor Facilitates Semi-Heterogeneous Dual Nickel/Carbon Nitride

- Magazine Articles

- Scientific Publications

- Areas of Interest

- Application Notes

- Events

- Jobs

- About us

- Contact

- HANU™ Flow Reactors

- Laboratory R&D

- HANU™ 2X 5

- Accessories

- Inlays

- HANU™ 2X 5 Inlay, cubic 2x2, stainless steel

- HANU™ 2X 5 Inlay, cubic 2x2, Hastelloy

- HANU™ 2X 5 Inlay, cubic 2x2, copper

- HANU™ 2X 5 Inlay, cubic 2x2, PTFE

- HANU™ 2X 5 Inlay, cubic 2x2, silicon carbide

- HANU™ 2X 5 Inlay, cubic 2x2, PEEK

- HANU™ 2X 5 Inlay, cubic 2x2, titanium

- HANU™ 2X 5 Inlay, cubic 1x1, Hastelloy

- HANU™ 2X 5 Inlay, cubic 1x1, Stainless steel

- In/outlet Ports

- Consumables

- Miscellaneous

- Inlays

- Accessories

- HANU™ 2X 5

- Process Development

- Pilot/Production

- Laboratory R&D

- MPDS® for Photochemistry

- Electrochemistry

- Previous Models

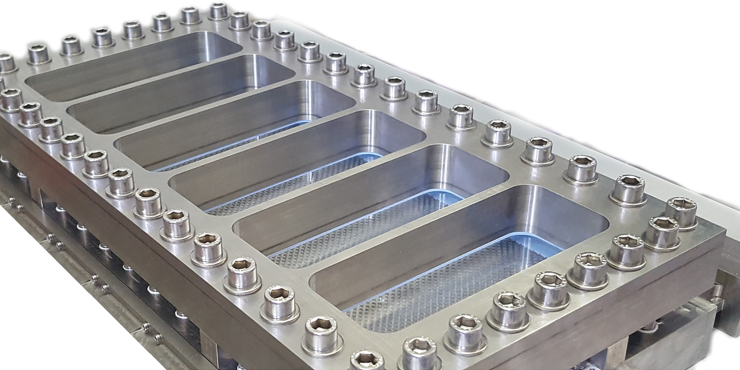

HANU™ Flow Reactors

The HANU™ flow reactor is designed and engineered to fulfill specific unmet needs in the flow reactor market.

Based on the COSTA™ Technology, these innovative flow reactors integrate numerous advantages as compared to the current state-of-the-art: a high mixing capacity no matter the flow rate, linear scalability by simply widening the process channel, and high customization potential. This goes without compromising energy or mass transfer while improving the process control.

The HANU™ flow reactors are assembled in a modular fashion allowing you to build the ideal reactor configuration to accommodate your chemistry. As such, the HANU™ flow reactor unlocks hard-to-perform chemistries that are traditionally difficult to scale.

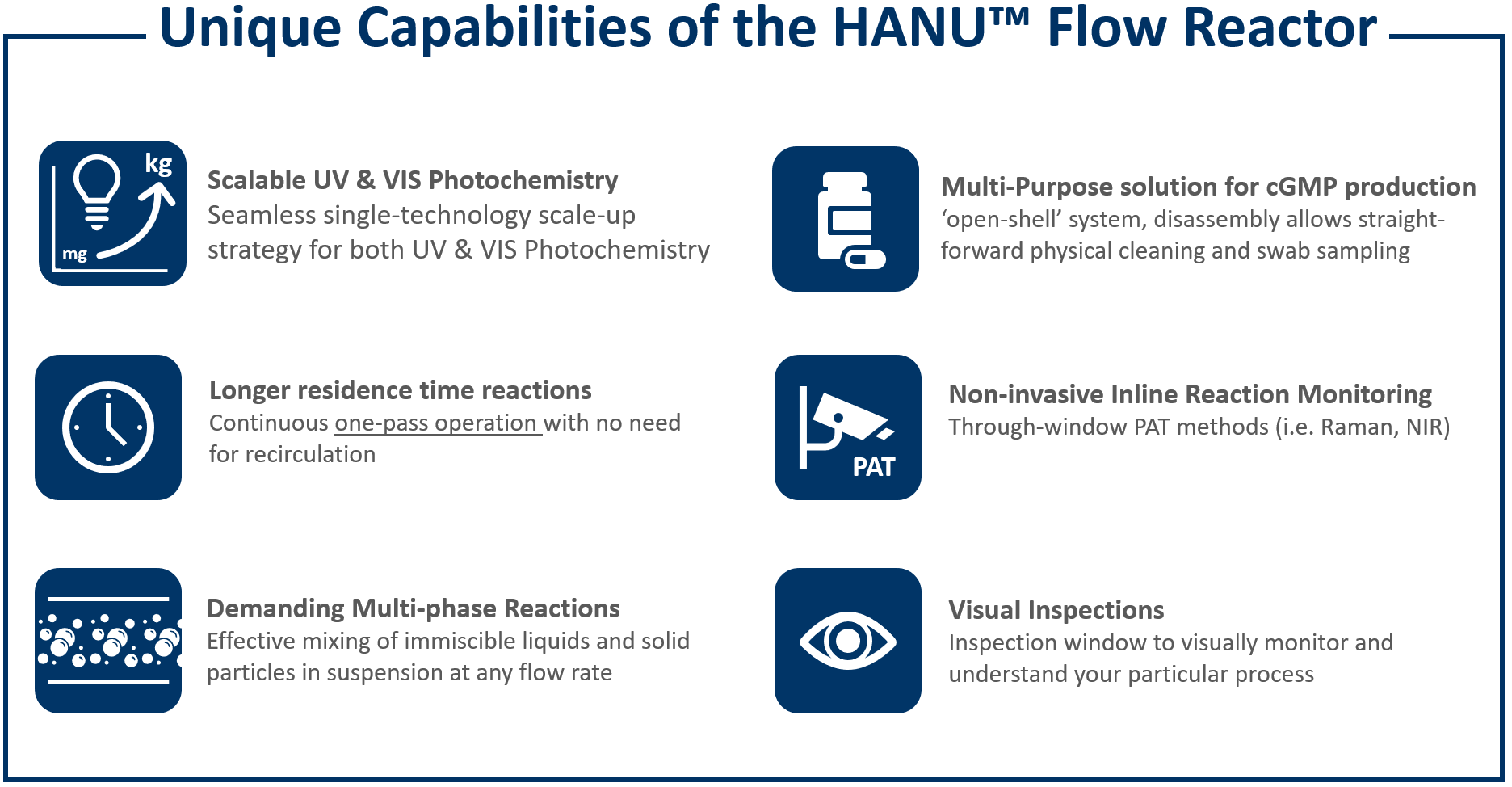

Scalable UV & VIS Photochemistry

Scalable UV & VIS Photochemistry

Both UV and visible light photochemistry can be accessed as the HANU™ reactor can be assembled with a large borosilicate or quartz window. In addition, the dramatically improved degree of turbulence in the process channels ensures fast film refreshment for optimal irradiance of your process stream. The HANU™ Flow Reactor can easily be scaled up by simply widening the process channel. This does not affect the specific irradiated area. If all other process parameters are kept constant, a seamless scale-up is obtained from the laboratory to the production scale.

Long Residence Time Reactions

Long Residence Time Reactions

Thanks to the COSTA™ technology, the mixing intensity within the process channel can be decoupled from the net flow rate. As a result, slower (photo)chemical reactions that require extended irradiation/residence times (up to the one-hour range), can be run in a continuous one-pass operation with no need for recirculation, while ensuring excellent control over the residence time distribution. This is a true game-changer within the field of flow chemistry.

Demanding multi-phase processes

Demanding multi-phase processes

Apart from enabling scalable photochemistry, the HANU™ Flow Reactor can be applied to scale up demanding multi-phase processes, as it allows the effective mixing of immiscible liquids and guarantees the processing of solid particles in suspension at any flow rate. The successful handling of suspensions containing heterogeneous (photo)catalysts, insoluble APIs or inorganic bases truly opens new avenues in scalable flow (photo)chemistry.

Multi-purpose solution for cGMP manufacturing

Multi-purpose solution for cGMP manufacturing

The HANU™ Flow Reactor complies with the Pressure Equipment Directive PED 2014/68/EU art. 4.3 and irradiation source can be delivered with ATEX certification. Since the HANU reactor is an open-shell system, disassembly allows straightforward physical cleaning and swab sampling of the process channels during cleaning validation cycles.

In this way, the HANU™ Flow Reactor complies with the strict requirements and can be operated as a multi-purpose reactor in cGMP manufacturing.

Non-invasive inline reaction monitoring

Non-invasive inline reaction monitoring

The application of through-window non-invasive spectroscopic analyses makes the reactor particularly useful for process development or integration in cGMP processes. Consequently, at every point of the process channel, the composition of the chemical matrix can be monitored via PAT methods. For instance, the point where 100% conversion is reached can be easily detected and the flow rate adapted to optimize reactor performance.

In terms of process development, kinetic data can be generated and plotted rapidly by means of PAT methods, such as Raman and near-infrared spectroscopic monitoring of the process stream.

An application note is available about the implementation of a non-invasive inline Raman spectroscopy as a tool for a real-time kinetic study of a Diels-Alder reaction.

Visual Inspection

Visual Inspection

As every chemist likes to look into their round bottom flask. The large transparent window of the HANU Flow Reactor is an invaluable asset that aids as an inspection window to visually monitor and understand your particular process. As such, the user may discern liquid-liquid flow regimes, identify color changes, detect precipitation, etc.